28

Scanning Stations

22

Assemblies

The Project Outline

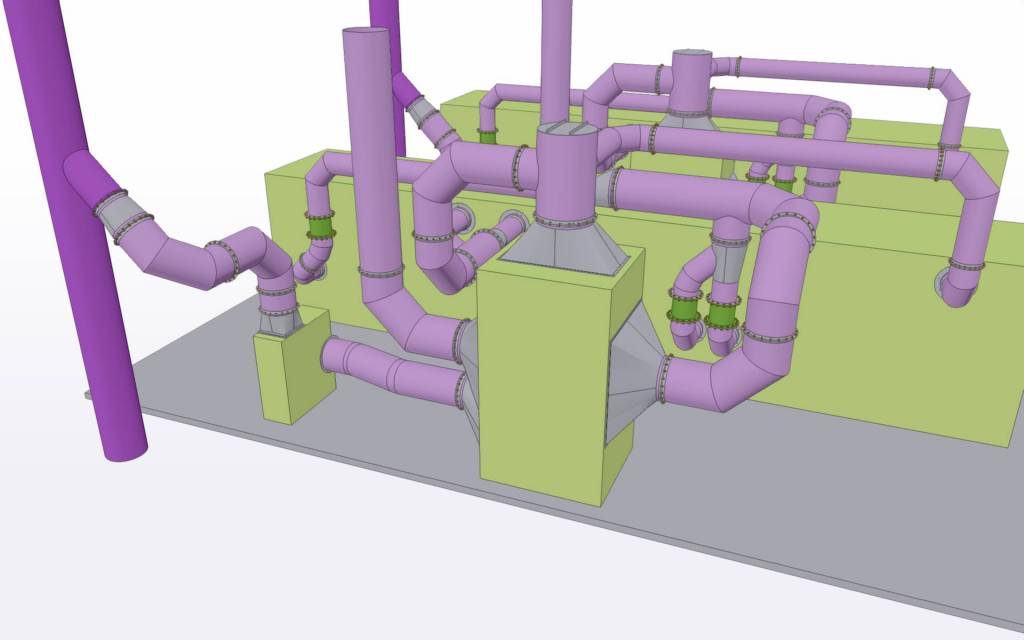

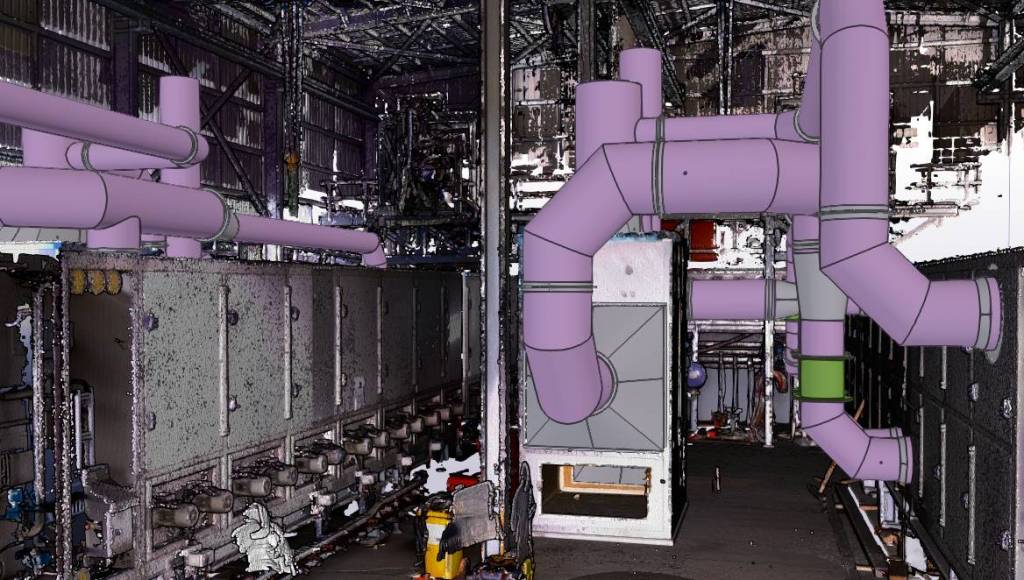

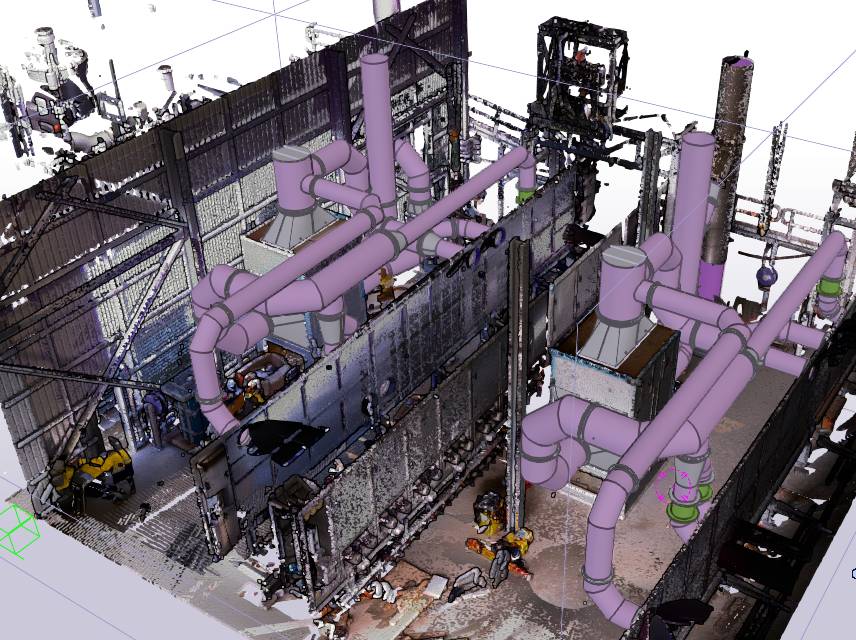

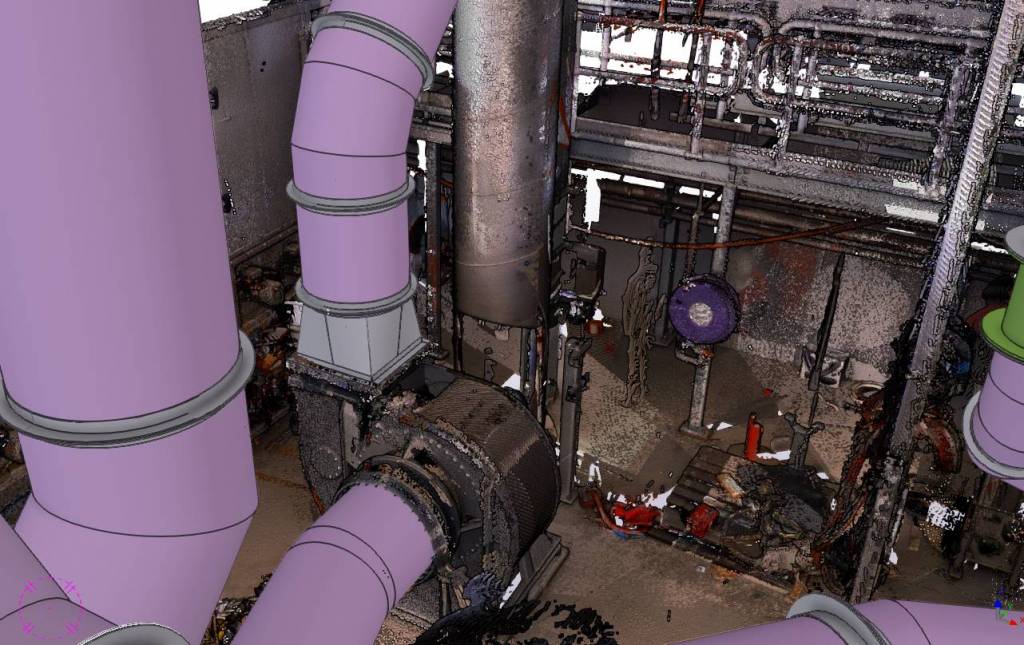

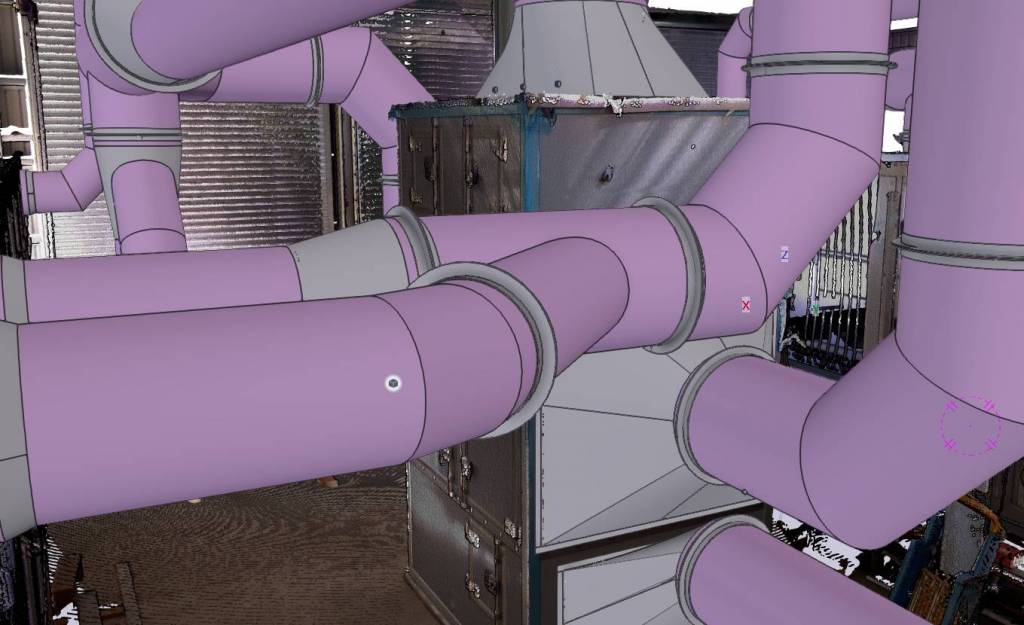

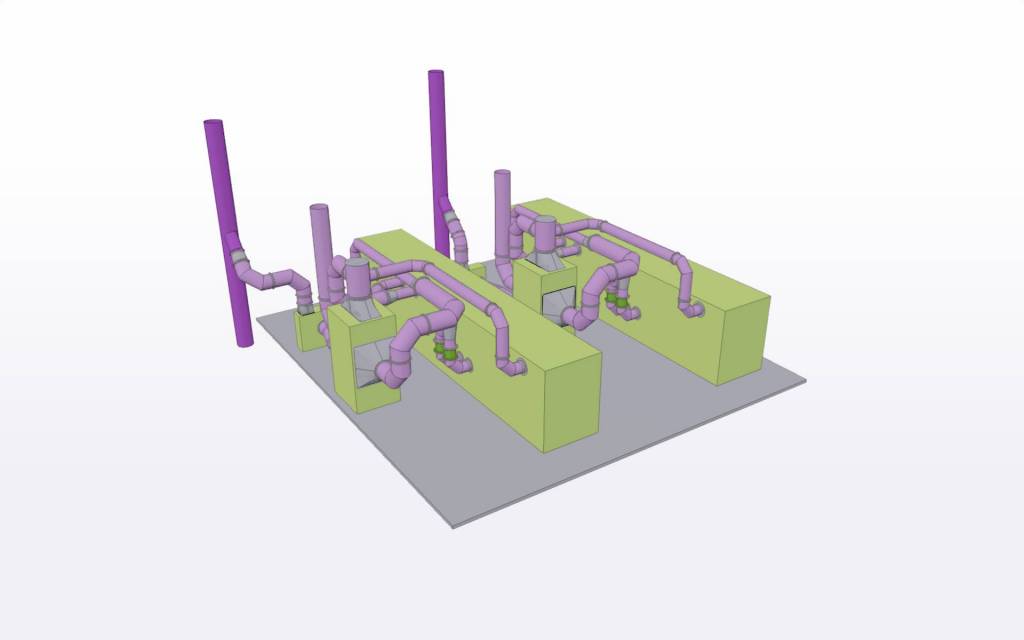

The Loganholme Biosolids Gasification facility upgrades was a landmark project delivering a revolutionary design for the gasification plant it is an Australian first initiative that demonstrates how sewage sludge can be transformed into energy. We had been assigned the task of site surveying the newly installed Dryers utilizing our Trimble X7 laser scanner to capture point cloud data so we could later align the new ductwork to the existing. We used Tekla structures to design & carefully align the new ductwork to the existing dryer with our point cloud overlayed in Tekla. When using our Trimble X7 laser scanner we collected a total of 28 scan locations within the facility which we then processed and inserted into the model to help detect clashes and the alignment as this was the priority. Steel detailing produced 16 assembly drawings and 28 part drawings with unfolder views of the pipework as well as 5 marking plans and an IFC model to help installation on site and setting out the steel. The process from start to finish combining point cloud data and steel detailing all in-house made delivery of this project seamless for our client.

Location

Australia

Queensland, Loganholme

Services Provided

- 3D Laser Scanning

- Steel Detailing

- Assembly & Part Drawings

- Marking Plans

- Clash Detection

Project Type

- Government

- Pipework

Year

2021